Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Conduct Your Shielding Game with Silver Precision!

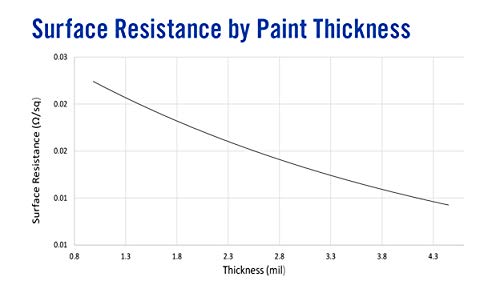

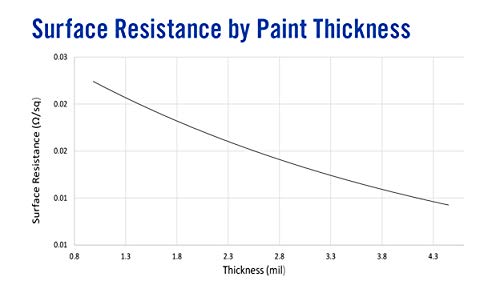

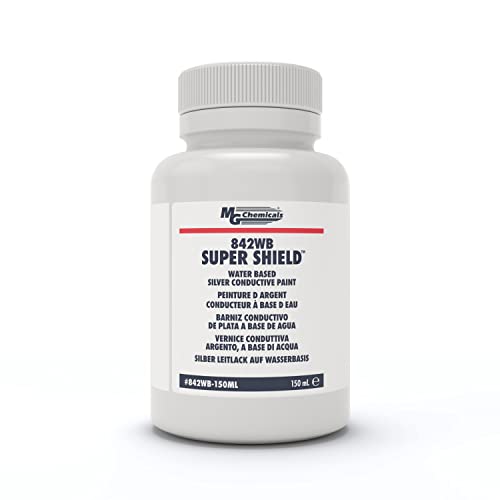

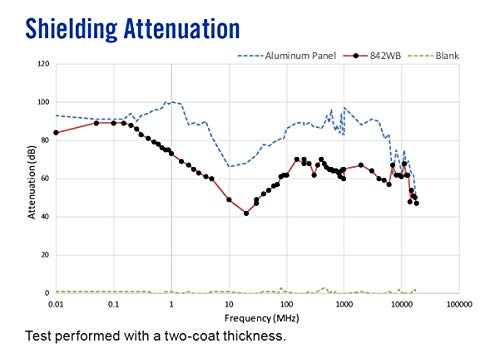

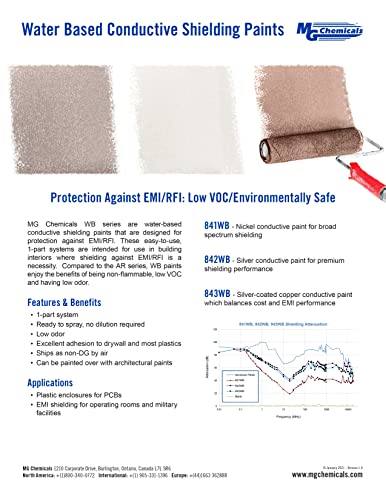

MG Chemicals 842WB Super Shield is a 150ml water-based silver conductive paint designed for high-performance EMI/RFI shielding. It offers versatile application options (spray, brush, roller), cures at room temperature without dilution, and provides a durable, paintable finish compatible with multiple surfaces. Ideal for architectural and electronic shielding needs, it complies with VOC regulations and is non-hazardous for air transport.

| ASIN | B06Y65PGQV |

| Best Sellers Rank | #31,736 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #42 in Industrial Coatings |

| Brand | MG Chemicals |

| Color | Silver |

| Date First Available | April 12, 2017 |

| Finish Type | Metallic |

| Full Cure Time | 24 Hours |

| Included Components | Super Shield Water Based Silver Conductive Paint, 150 mL Bottle |

| Indoor/Outdoor Usage | Indoor, Outdoor |

| Item Volume | 150 Milliliters |

| Item Weight | 7.9 ounces |

| Item model number | 842WB-150ML |

| Manufacturer | MG Chemicals |

| Model Name | 842WB-150ML |

| Package Information | Plastic Bottle |

| Paint Type | Watercolor |

| Product Dimensions | 1 x 1 x 1 inches |

| Size | 150 mL |

| Special Feature | RF Shielding |

| UPC | 779008842317 |

| Unit Count | 1 Count |

L**O

FIXED THE TOUCH PADS ON MY NOVATION CIRCUIT!!!

One day, I go to turn on my Novation Circuit and it's freaking out! She was making her own chaotic dubstep madness without my permission! That said, dubstep is not where I am at in life right now!!! I was saddened by this and my feeling was hurt. I looked for similar instances of possessed Novation Circuits online and found that I was not alone in my pain. There was only one thing to do... take it apart! Pulling the sulicone(rubber) pad off the bottom was a pain but not impossible. I peeled the pad back carefully as to not stretch it or tear it. Screws ahoy the rest of the teardown was simple. When I got inside the box it was pretty filthy. Dust is said to be the culprit in this specific malfunction and jeezus holy merry was it a grandmother's old jewelry box stuffed in the back of the closet, inside the Circuit box! Surprisingly there was no dust between the plastic contact layer and the copper touch circuits. All I had at the time of autopsy was acetone so I cleaned the copper contacts and then started wiping down the plastic contact sheet with the printed black conductive paint. DONT USE ACETONE ON THIS STEP!!! Stupid me, I started wiping off the black conductive paint almost immediately! I repeat... DONT USE ACETONE TO CLEAN ELECTRIC CONTACT PAINT!!! I was further saddened and my feeling was nearly crushed at this point! Did I give up hope and call my fun little beat box a wash? HELL NO!!! This just meant I got a little work to get done! The internet was hopeless on information on fixing pressure pad contacts for synths. I had to get creative! So I took to Amazon for assistance of course!!! Searching for electric contact paint led me to this product. As I use MG Chemicals for other DIY electronic projects I knew I could put my faith in their products and potentially bring my Novation Circuit back to a jam worthy state. It wasn't cheap for a can of paint but it was up the bizniss of what I thought I needed to do the thing I gotta do. After receiving the can a few days after hitting purchase, it took weeks too fester the bullocks to get on it... I did today... I did a test spray to compare resistance between the factory paint and the MG Chemicals paint. The MG was nearly if not more than double the resistance between distances but this was all I got and by golly gee whiz I was gonna do it anyways!!! Plus if it didn't work I still have a whole can of acetone by my side! So I cleared the rest of the factory contact paint with intention this time using acetone to give me a clean slate. Carefully masking off the area around the square pockets I prepped for spray pretty darn well and was proud of my work. I sprayed 2 good coats and a light finish coat pretty evenly. Not having a "clean room" sucks because dust loves fresh spray paint... all was not lost tho! Zona (another great item on Amazon) makes really fine sanding cloth. After a sufficient dry time(10-15 minutes(I have no patience for drying paint)) I started with 1200 grit and sanded the 3 particles of dust right down smooth and it hopefully evened out the pads to an even whatever... 2000 grit felt like a good grit to stop at as that's where my patience gave in and satisfaction settled. I then peeled back my masking job only for my pride to get bent a little too now. I reached again for ol' trusty acetone and made the best of what I could with the overspray that went under my proud masking job. It was sufficient enough at some point and the advice of an old Asian gentleman I once knew came into my head and said, "No Touchy Too Muchy!" Again with a settled satisfaction I moved on... I vacuumed everything twice and assembled the Circuit slowly and carefully knowing that this is when it usually goes wrong. Once again I dreamed of a dust free filtered clean room but who the hell has one of those in their shop!?! You just gotta do the best you can sometimes! Everything reassembled nicely and I even used a double stick tape to re-adhere the silicone bottomous. The time for redemption had come... my feeling was no longer hurt but was now anxious. I found a fitting plug and nodded to the powers that be... BEHOLD!!! She powered up better than before! At least I feel she did! Little Circuit's demon was exorcised! Her days of dubstep were long gone and her beats started making sense! She was off the Crack and back playing a groovy house beat like the good ol' days! Thank you MG Chemicals!!! You really did a service today saving the life of a groovy little beat box! ...not the best beat box I own but now I have a really deep personal and intimate relationship with the little Circuit and will always carry with me the fond memory of the day I saved my Novation Circuit thanks to MG Chemicals and their availability of some pretty unique products! Needless to say the sadness I had dulled long before I began working on this which really helped. I was not in a rush and the anxiety of losing my Circuit diminished. This became a case of learning from mistakes and bringing a new tool into my potential repertoire. I am happy all has worked out thus far and I can carry forth into my days knowing 1, when and where to use acetone B, MG Chemicals has my back and 3, It's not impossible... there is always a way! As for my feeling... rest be assured, it is safe as it should be...

N**7

Fantastic stuff, I swear by this.

I am heavily into DIY electronic projects, most of which involve high gain, high impedance amplifier circuits that will buzz just by having a 1" section of input lead exposed. SO, I really need shielding, like really really. I designed a small array of universal boxes for breadboards and my various projects, and I 3d print them as needed, using mainly ESun ABS+ but also the occasional straight ABS or PETG. This stuff sticks fine to all of my plastics, and the little 150ml can goes a surprisingly long way. One thing - I noticed halfway through the can that the bottom had a deep sludge in it, about 1/2" to 3/4" thick, that was coagulated material. Reading another review here, I saw that he had used acetone as a thinner, and I decided to go for it and add some to try to stretch the can out by getting that sludge back into service. It worked *perfectly*. Pleased with the results but thinking I could benefit from making the paint even more thin, I added more acetone until the paint was very water-like, but still strongly silvery. I *really* like it like this. It flows beautifully and it's much easier to coat a surface before it's sludging up from drying, and it still dries super fast because, of course, acetone. If a spot looks too thin, like I can make out the underlying material, I just dip the tip of my brush in and swipe the area. Before I thinned it like this, my work would come out looking smeary, a bit like stucco. Now it looks much more pro, much more even and smooth. Clipping a meter (BK Precision 2405A) lead to one side of the last project box I did (for small breadboards, box is about 6"L x 3"W x 2"H) and probing around with the other lead, I get an almost perfectly consistent 4.8 ohms, and that's with a single coat all the way around the inside. I can't say enough about this stuff. I used to get the aerosol spray version but had lots of problems with it clogging up on me. Got a can of this thinking I might hate it, but oh **** no. I love it, and I'll never go back. Properly thinned, it's a dream to use, wastes next to nothing but a single brush and maybe one spilled drop, and it isn't flying around in the air. I can do a dozen boxes (and lids for them) easily on one can. Yes, its expensive, but it works GREAT, even for superhigh gain, superhigh impedance circuits like my LMC6081 op-amp projects. Truly wonderful stuff and if they ever stop making it, I'll be really lost. Thanks MG Chemicals! :-) Rick NR417

K**S

way overpriced , but effective.

The manufacturer is sly about what it is and doesn't give much documentation on application and usage. It took a lot of research to find that you need acetone for clean up even. You could probably make some sheilding paint up as good or better, but in the time it took the high expense of this paint won out again my overall available time. It works for radio frequency sheilding in guitar cavities. It sticks well and cures quickly. there is a little bit more than necessary to do all the cavities front and back , including tremolo recess on a stratocaster with S S S routes including output jack cavity. Probably enough for multiple guitars with less area to cover. In so much as the other intended uses like painting pcb boards and what not, I couldn't say. My only experience is using it as RF sheilding for guitar switch, jack, pickup and tremolo cavities. For that it did the job.

C**N

I've bought a few of these cans now, it's amazing stuff. Dries quickly and with far better performance than other materials. However, like some other reviews have mentioned I've had my first defective can. At £60 a pop you'd expect a lower failure rate!!

T**Y

Did three coats of the electronics pocket and pickup cutouts. Only took a little light sanding to knock the gloss down from the clearcoat and it stuck nicely. Excellent conductivity. As others have noted it does have an odour (I thought it akin to a tin of smoked mussels) but the odor goes away once dry. Make sure you spend time doing your surface prep and it's a breeze. Also, use a stir stick of some kind and spend a few minutes really mixing it well. It clumps at the bottom after only an hour of sitting, so you need to make sure you agitate it well before using.

M**K

Adheres well to PLA/ABS(+,+.) Flexible enough that it won't bend with minor lateral stress to ~0.4-0.8mm walls. Coating a few mils on surface (and ensuring it fills layer lines) makes for a very good EMI/RF shield for PCB casings, the reason I got the product. Cures/dries very fast, and being water-based means you can wash it off from tub (and thus don't waste an acid brush & plastic container, unlike with epoxy-based/solvent-based EMI/RF shielding composites.) Overall, very pleased- reduced the EMI/RF-induced noise on my sensitive mixed-signal PCBs massively- much more than MG's carbon-based coatings. Just be aware that a little goes a long way with this- and it's best to keep it refrigerated once you've opened it (it dries quite fast, and the seal on the bottle isn't special- it's just a regular twist cap.) You don't want to put it in the freezer as you can with some solvent-based applications- being water-based, it will gel up beneath 0C.

R**H

Its good

R**A

Product is good, but the price doubled in a month! Seems very opportunistic

Trustpilot

1 month ago

2 weeks ago