Some deliveries may take a little longer than usual due to regional shipping conditions.

Customer Services

Copyright © 2025 Desertcart Holdings Limited

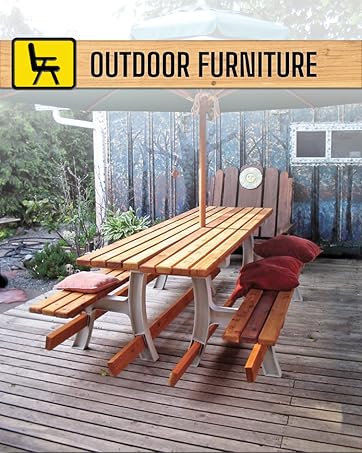

🔄 Transform your space, one flip at a time!

The Hopkins 90110 Flip Top Bench is a versatile, American-made furniture piece that converts effortlessly from bench to table using a patented slide-lock mechanism. Customizable up to 12 feet in length, it supports seating for up to eight when paired, and features heavy gauge resin brackets for durability. Ideal for indoor or outdoor use, it combines practical design with long-lasting quality to elevate any gathering or workspace.

| ASIN | B0015XGCN0 |

| Best Sellers Rank | 415,352 in Garden ( See Top 100 in Garden ) 1,002 in Garden Benches |

| Customer Reviews | 4.4 4.4 out of 5 stars (3,095) |

| Date First Available | 7 Aug. 2012 |

| Department | mens |

| Item display height | 25.5 inches |

| Item display weight | 6.35 kg |

| Item display width | 6 inches |

| Item model number | 90110ONLMI |

| Item volume | 67001 Millilitres |

| Manufacturer | Hopkins Manufacturing |

| Material type | Resin |

| Part number | 90110 |

| Product Dimensions | 15.24 x 71.76 x 86.36 cm; 5.9 kg |

N**Y

Highly recommended.

We bought 2 of these benches in spring last year and have been delighted with them. We chose to stain the wood and both timber and frame have survived the winter and look as they did when first put together. We are always complimented and asked for purchase details by our guests so they can buy too. The benches took me (lady of adequate assembly ability) 30- 45 mins each to assemble. I would definitely recommend painting/varnishing your wood before putting the bench together. Our wood was obtained by a local timber merchant who cut it to our desired length. I think it can be anything from 2ft to 12ft? Anyway we chose 4ft. £20 for the lot. Benches work well as a picnic bench when we are eating outside as a family and also work well separately as benches (with a backrest) for seating when we've had garden parties. My husband is 6ft 4 and sits comfortably when the table is up in the picnic bench position. Hope this helps you in your decision making.

W**Y

Simple build

Very pleased, easy assembly, looks well easily adapts

S**B

Great choice

This works well. It's solid and substantial when built. Sanded down dry, tantalised wood and used garden paint on it. Transition from seat back to table takes seconds. A little chiselling out of some grooves, for the bottom crossbars to fit into the slots.

Z**D

Very nice when completed

Very nice when completed, but not that easy to put together. Also UK 2 by 4's are thicker than the ones to fit the bench, so the wooden slats needed to be shaved down to fit.

D**N

Five Stars

Good and quick to make though measure the holes before u go buy the wood.

K**R

Five Stars

What a fab thing....made up and treated in a week....

J**L

thank you goods arrived

My neighbour is very pleased with his new table /bench and has made it to fit the space he has .Thank you

K**A

Make sure you can buy correct timber first before purchasing

It was really hard to get correct wood for the bench you will need to account another £50 for the timber for each bench we have managed to finally get some from homebase when they received new stock. What's in the box is no much just plastic legs with neat design feature to be flipped over and pack of screws I must say it is sturdy but if you get incorrect wood it won't be a smooth assebly every holes are just so to hold the timber in place any thinner wood will not fit. Make sure you can buy the timber somwhere first before getting those legs returning this purchase proves very difficult and expensive. Had to wait a 1month to find wood in stock locally.

م**ى

الطلبية ناقصه لا يوجد خشب هاذي ثاني مرة اطلبها والطلبية ناقصه للأسف

H**Y

I gotta tell you, these bench kits are GREAT. For less than $50 bucks I was willing to give this a try. Home Depot had ground contact pressure treated 2x4's in 6 foot on sale for $3.75 each. Good pressure treated lumber, already cut to 6 foot. (Hot TIP: I know it says you can, but I wouldn't go with 8 foot wide. Not only does it make it really heavy, but it will be a little spongy in the middle). 6 Foot seems to be a perfect size. I loved the idea of it converting to a table AND putting 2 together back to back for a full size picnic table. But would it really work "as advertised", be stable and nice looking. Yes, yes and yes to all three questions. I used a neutral semi transparent 4 year stain/sealer on the pressure treated wood. You could use regular 2x4x6's, but you know what happens to untreated pine sitting outside 24x7x365. It will rot within a couple years. Pressure treated 2x4 rated for ground contact should be around a LONG time. Don't even need to stain it, so long as your ok with it going gray, and crack/checking a little. Mine is to accompany a recently built screen house with some outside seating, so I sealed it with the same stuff used on the screen house. I love this and it is just what I had in mind. The doubling as a table is perfect for my application. By the way, the mechanism to fold the bench back into a table works well and locks into place. Overall the unit seems very sturdy and should stand up to the elements well. A few building tips in the next paragraph if your interested. If your not going to stain or seal the lumber, no problem if its pressure treated lumber and you don't mid the fade to gray and some wood checking. 1) However if you do stain or seal the wood, sand it a bit first, or you'll need to wait until good and dry before you seal it. Just like a new deck with pressure treated lumber. Pressure treated lumber comes with a surface coating meant to hold in the penetrated treatment. Often stain or sealer simply won't stick or penetrate. A light sanding allows the sealer/stain to penetrate and still allow the boards to "gas out". While your at it hit the edges of the boards to give them a more finished look, rounding the sharp ends a bit. I couldn't stand waiting, so I sealed after putting it together and allowing a few days strong sun drying. 2) Pick out really straight and true 2x4's. Warped ones are a no go here. I found not all of my 6 footers were exactly the same length. Some were off by as much as 3/4". So I simply cut them to be certain all were EXACTLY the same length. Take your time putting it together so you have even flush ends all the way around. An extension on your drill/driver is helpful for getting it into a few of the tight places where screws are needed. The kit will be a 1-2 project on a project scale with 5 being hard. All you need is a drill/driver for pilot holes and driving screws, and a circular saw to be sure the boards are all the same length. If your careful picking out the lumber and find 6 foot pressure treated 2x4's, you may not need the saw. I have bought a second one and 9 more pressure treated 2x4x6.

A**R

The bench itself was simple and straight forward to assemble with some prep work ahead of time. The quality of the bench really depends on the time taken to prep the boards used as the frame is self is not too complex. I fully recommend getting a flexible drill attachment to get to some of the harder to access screw holes. As others pointed out the frame can break/bend at screw holes if the drill is too strong so I recommend just lowering the torque setting on the drill motor so it would just stop screwing in before bending or breaking the frame and it worked perfectly for me. I used some scrap wood to connect the top and seat boards together before attaching to the frame. Key there is to make sure you have the width of the top boards spaced to fully cover the frame attachments. I used an extra paint stir stick cut up as spacers, 3 sticks wide on either side about did the job spacing between each boards. When attaching the table I broke from the directions and did the support board first. Then laid the 3 board seat already connected upside down on a saw horse and set the frame on that so I could pre drill holes and then just screw in the seat to the frame. As for the top I laid down towels so not scrape the finished seat and tops paint job and leaving the frame unlocked but fully assembles to get the distance between the two frames measured perfectly rather than attaching the adjustment points while not on the frame. I could set it at an angle on the upside down top and mark every hole, pre-drilled then realign frame and screwed it in. I went with 5 ft 2x4 boards. I had the hardware store cut 5 10ft boards in half as it required 9 5ft boards to build. So all I had to do was sand and round the edges of the boards to give them a softer texture when sitting on the edge. I added wood filler to fill in any knots or imperfections and then painted them with a nice semi-gloss exterior paint to protect from water and wear and tear. Took me longer to sand, add wood filler, and paint the boards than it did to assemble the whole thing. I did notice a little squeak between painted wood and the frame so I wiped down the friction points with some finishing wax to "grease" the areas and it helped some so when sitting on the bench I don't notice much noise at all. Table and Bench work well in their respective forms and easily transition between the 2 just by pulling out the 2 locks on either side. Its a fun easy project and if I ever build a second one I can have socially distant picnic tables during quarantine in 2020 and beyond. I liked the blue color so much it took me a day before I wanted to put it outside in the rain but the semi-gloss let me wipe down the table easy. Might be nice for interior as well in rooms right up against windows where you want to work at a table while looking out but then fold down to a bench when you have company inside. Good minimalist functionality in my opinion. I like products that can serve multiple functions with minimal effort transitioning or moving them.

D**K

I saw some of these at my neighbor's beach house and determined they would be perfect for our deck as well. Some key point to make yours as successful of a project as ours! • Get treated wood • Cut down to specs listed • Leave about ½ inch extra (braces) • Let the wood dry out (2+ weeks) • Place the wood in a dry area • Place on small spacers (for drying) • Rotate/Flip every few days • Rotating keeps wood from bowing • Stain as dark or as light as you want • Get Outdoor Oil Based Polyurethane • I used 3 coats • Plan on re-coating annually or so • I painted mine Black (like iron) • Mine required post-touch up paint • Paint scratches off pretty easily • Paint still looks good just touch up • Use Washers on each of the C-Cuts • Washers not listed in instructions • The washers provide BEST stability • Remember cut braces slightly longer • Longer Braces more space for C-Cuts • More space C-Cut screws/Washers This was a fun, easy, not too time consuming project. It was my FIRST TIME ever working with wood, building anything. My neighbor gave me the type of wood and type of polyurethane tips, the rest was just my ideas on how to make these more sturdy based on my observations of my Beach Neighbors bench/tables they had on their deck. This is a buy and project worth every minute! We love them and use them all the time. Cut ours down to 5 feet long. *****HIGHLY RECOMMENDED*****

D**H

As described, well made, works well. Nice that you can customize the width. Once assembled the bench is pretty sturdy and very heavy as it includes nine 2x4's for which you probably chose pressure treated boards. The instructions are pretty bad though, so think things through carefully before you start and have the right tools which is a bit more than recommended. First problem is when assembling the table top / bench back, the picture shows two pieces with slots having a "V" at one end, pointing toward "front". The "V" actually goes toward the back. For "front", strictly follow the stamped wording "front" on the pieces themselves, not the image in the instructions. The worst that will happen though is if you intend for the boards to face a certain way, front to back, they will be assembled reverse. The next issue with the instructions is that the seat bench is assembled last, with the table/back attached. This is nearly impossible. I recommend that you do not attach the table/back until the very last, or if you do attach it to see it work, take it back off. Arrange the seat bench boards on a workbench or project table, sit the legs with stringers in place upside down on top of those, then screw the farthest one from you down first. This will stabilize things until you can screw down the other two seat boards. Then screw down the stringers, flip it right side up, then you can put the table/back on. Finally, it is really hard to drill pilot holes with the boards in place unless you have a very long drill bit or use an extension for a drill having a hex base for a socket. If you use new pressure treated boards, you probably don't need pilot holes anyway, just screw it down. For that you definitely need either a very long screw bit or use an extension. There is no way your drill and normal size bit fits without angling all the screws. Also I recommend not putting the bench boards flush front and back with the edges of the stand. Let them overlap about 3/8 inch so there is a little lip between the board and plastic. All that said, it is not hard to assemble if you have the right tools and figure out how it goes together before you start. And you end up with a heavy sturdy bench / table that works very well.

Trustpilot

3 weeks ago

1 month ago